Background:

An industrial gas production plant in Monterrey, Nuevo León, Mx, faced challenges related to high water consumption in its cooling systems. This led to the search for improvement projects and solutions that needed to address the following aspects:

-

Lowering the costs of disposing purge water from the cooling tower.

-

Maintaining efficiency in heat exchange without compromise.

-

Reducing chemical consumption in water treatment.

-

Minimizing the frequency of fouling in heat exchangers and cooling tower fill, in order to extend corrective maintenance intervals to every two years.

Proposal:

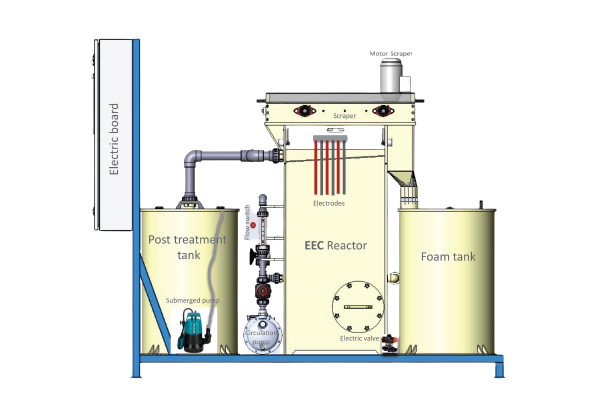

With the primary objective of improving the cooling process to achieve significant water savings—and, consequently, economic savings—GRACO proposed a series of tests using Electrolysis Technology (EST). This innovative, environmentally friendly technology provides multiple benefits.

EST allows for an increase in the concentration cycles of the cooling tower, resulting in significant water savings without the use of chemicals.

Results:

The EST equipment was operated for six months, during which several variables were adjusted to achieve the optimal conditions. The implementation resulted in a 19% reduction in cooling tower make-up water consumption compared to the same month of the previous year, representing a saving of 2,327 m³/month.

Chemical usage was also reduced: sulfuric acid consumption decreased from 3,150 kg/month to 2,550 kg/month, and sodium hypochlorite consumption dropped from 4,640 kg/month to 3,520 kg/month. Additionally, the efficiency of the heat exchanger was maintained, as shown in Approach Graph 1.3.

Conclusions:

-

The water savings achieved during the final project tests were:

-

Cooling tower purge water savings: $2,472.62 USD/month

-

Cooling tower make-up water savings: $11,053.25 USD/month

-

Total monthly water savings: $13,525.87 USD/month

-

This resulted in a return on investment of just 8 months.

Our client, a company with strong presence in Mexico, achieved significant savings in both water consumption and disposal while ensuring the productivity of its processes. This translated into a considerable reduction in operating costs, thanks to the expertise, support, and service provided by Graco.